Gevelridder Vacuum Lifters – the lightest and strongest in the world

Discover Gevelridder vacuum lifters — the lightest yet strongest in their class.

Standard capacities 150–400 kg, available fixed or rotating, and up to 2,500 kg on request.

-

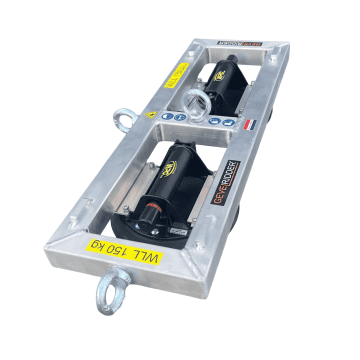

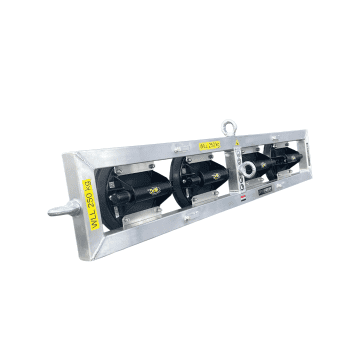

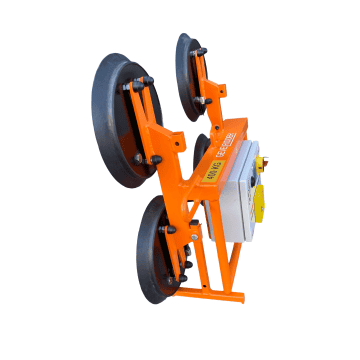

SirLiftAlot Series: manual hand-pump lifters, Safety Class 1

-

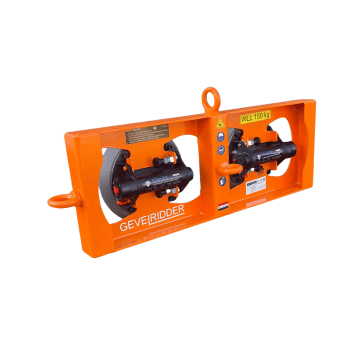

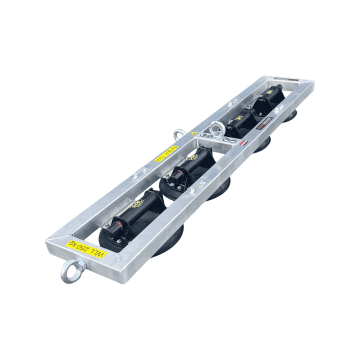

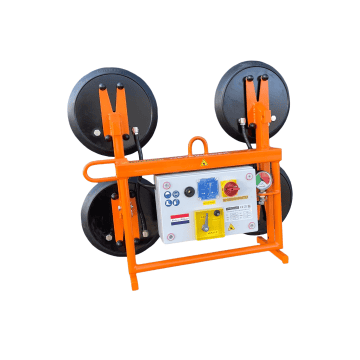

KIM Series: electric auto-vacuum lifters, also Safety Class 1

→ Both ranges made from high-grade aluminium — ultra-light, robust and low-maintenance -

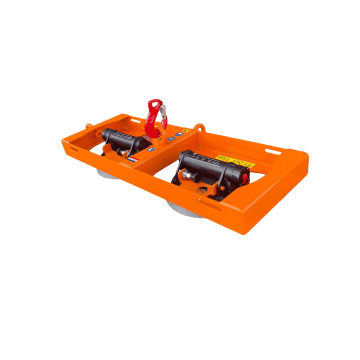

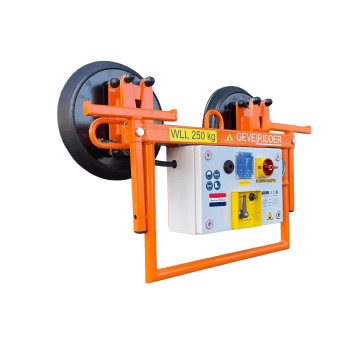

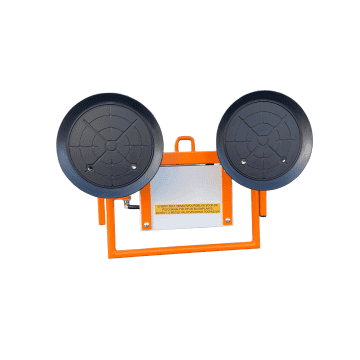

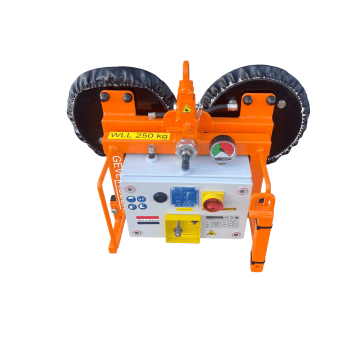

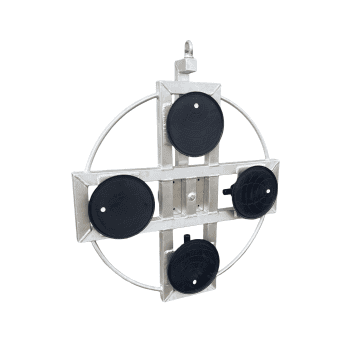

V Series: Safety Class 2, bead-blasted and powder-coated steel — ideal for heavy-duty, demanding site work and glass installation

-

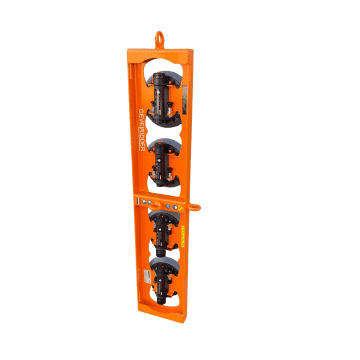

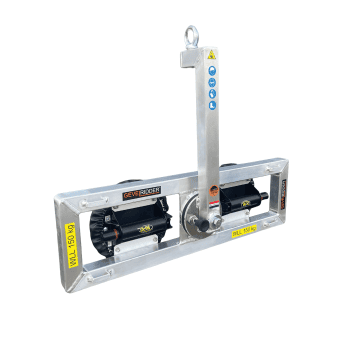

Battery-powered Class 3 lifters: 100% dual-acting with fully independent vacuum circuits — available on request for maximum safety in professional industrial applications

See the product listings below for details on applicable safety standards, directives and use cases.

Compact Power for Safe Lifting – Gevelridder Vacuum Lifters

These compact and powerful tools make it possible to lift and handle heavy or fragile elements safely and ergonomically– without straining the back and without relying on large lifting machinery.

Whether as a vacuum lifter, suction device, or glass manipulator, Gevelridder offers the perfect solution for every job site.

Why Every Job Site Needs a Professional Glass Lifter

The advantages of a high-quality glass lifter are clear:

✅ Back-friendly operation thanks to safe vacuum lifting

✅ High precision when positioning glass, doors, or panels

✅ Reduced manpower for lifting and holding

✅ Versatile use for glass, stone, sandwich panels, and more

✅ Ready to use immediately – no external power or compressed air required

Thanks to their compact size, all models fit easily into a van or service vehicle. You’ll always have your own lifting system ready – on site, in the workshop, or during installations.

Lightweight, Strong, and Built to Last

Gevelridder vacuum lifters are engineered from high-quality materials for daily professional use.

-

The SirLiftAlot and KIM series are made from high-strength aluminium, combining maximum stability with minimal weight – ideal for workshops, indoor installations, and lifting up to the first floor.

-

The V series is built for heavy-duty and outdoor use. Each steel frame is bead-blasted and powder-coated, making it highly resistant to corrosion, weather, and wear. These models are classified as Safety Class 2, equipped with an integrated pressure-drop alarm, and suitable for higher elevation work – even above the first floor.

-

On request, battery-powered lifters in Safety Class 3 are available, designed with 100 % dual independent vacuum circuits for maximum safety in industrial and high-risk environments.

More Than Just a Product – A Partner for Professionals

For over 30 years, Gevelridder has stood for quality, safety, and innovation in lifting and installation technology. With in-house product development, field experience, and expert consultation, we provide far more than great products:

✔️ Reliable customer support

✔️ Personal advice to select the right model

✔️ High availability and fast delivery

✔️ Fair pricing and top-tier quality

Professionals know: working with Gevelridder saves time, prevents back strain, and eliminates unnecessary compromises.

Safe Lifting with Vacuum Lifters – in Compliance with European Standards

1. Legal and Technical Framework

Gevelridder vacuum lifters comply with the European Machinery Directive 2006/42/EC, the EN 13155:2020 standard(non-fixed load-lifting attachments), and the EU Occupational Safety Framework Directive 89/391/EEC.

Under EN 13155, every vacuum lifter used for lifting must be designed to prevent load release in case of vacuum failure. This can be achieved through:

-

A secondary mechanical safety device (e.g. safety sling or strap), or

-

A dual vacuum circuit system – two fully independent vacuum systems, each with its own reservoir, check valve, and visual/acoustic alarm.

Additionally, the standard requires:

-

A two-action release system to prevent accidental load release.

-

Visual or audible warning devices for low vacuum levels.

-

Regular inspection and maintenance as part of a company’s risk management.

All Gevelridder vacuum lifters carry full CE conformity and are supplied with the required Declaration of Conformityand Operating Manual under the Machinery Directive.

2. Gevelridder’s Safety Philosophy

Our guiding principle: “Double is safer – and additional is best.”

Wherever possible, we combine a vacuum system with a mechanical secondary safety device. While a dual vacuum circuit prevents pressure loss, it cannot prevent glass breakage or slippage – hence the importance of redundant safety measures.

Gevelridder products fully meet EN 13155 requirements, available as:

-

Single-circuit systems with mechanical safety backup, or

-

Dual-circuit systems with separate reservoirs, check valves, alarms, and two-action release.

This guarantees the highest level of operational safety, even under demanding construction conditions.

3. Risk Assessment and Inspection

Before every use, a risk assessment (comparable to a workplace safety analysis under EU Directive 89/391/EEC) must be performed, considering:

-

Selection of the correct vacuum system (single or dual circuit),

-

Need for a secondary mechanical restraint,

-

Marking and isolation of fall zones,

-

Maximum working height,

-

Environmental factors such as wind, slope, and stability.

All vacuum lifters must be regularly inspected and documented by a competent person in accordance with the manufacturer’s instructions and European safety standards.

4. The 1-2-3 Safety Level System

To provide clear guidance for users, Gevelridder applies the 1-2-3 Safety Level System, aligned with the Eurocode consequence classes (CC1–CC3). The higher the potential risk, the stricter the safety requirements.

| Level | Work Situation | Vacuum System | Secondary Safety | Fall Zone Isolation | Max. Height | Typical Use |

|---|---|---|---|---|---|---|

| 1 – Low Risk | Workshop or indoor use, glass ≤ 1.2 m above floor, < 1.8 m to lifting point | Single-circuit manual vacuum lifter | Not required | Required | ≤ 1.2 m | Indoor transport, preparation work |

| 2 – Medium Risk | Limited height (up to 2 floors) | Dual circuit or single with safety backup | Required | Required | ≤ 2 floors (Gevelridder up to 1 floor) | Factory hall, low-rise sites |

| 3 – High Risk | Outdoor site, large heights > 1.8 m, public area | Dual circuit mandatory | Required | Fully cordoned | > 3 m (not for standard Gevelridder models) | Facade work, crane operations, urban projects |

Gevelridder lifters are intended for Level 1 and 2 operations.

For Level 3, industrial-grade systems with advanced safety features are required.

5. Practical Use

-

The SirLiftAlot and KIM series are designed for low-risk applications – ideal for workshops, indoor projects, and heights up to one floor.

-

The V series is built for higher and more demanding environments, with steel construction, powder coating, Safety Class 2, and a pressure alarm system – perfect for outdoor and elevated work.

-

Battery-operated Class 3 models, featuring 100 % dual vacuum systems, are available on request for heavy industrial use.

6. Conclusion

Safety, ergonomics, and precision define the Gevelridder standard.

Our vacuum lifters combine technical excellence, field-tested reliability, and full compliance with European regulations.

Whether aluminium or steel, single or dual circuit – Gevelridder always provides the right solution for your project, ensuring maximum safety with minimal effort.